Wax carving advent calendars?Wax carving advent calendars?

Shrinkage in lost wax casting

Every teacher I’ve had has had different opinions about shrinkage and how to prepare your wax for it. One thought every ring had to be 1 size bigger, while another thought it should be 1 size smaller. Others thought half a size bigger would be enough. Or was it half a size smaller?

I was SO confused. I wanted one set of rules to follow, not all these contradicting ones.

I decided to just experiment. Send waxes for casting and see what happens. By doing that, I’ve found my own way of handling shrinkage. (Which is exactly what my teachers had done as well. Their methods of dealing with shrinkage were just very different from each other.)

Below is my way of dealing with shrinkage. You can try if it works for you. If it doesn’t, adapt it to a way that works best for you. There isn’t really a wrong or right way here. Just personal preference and experience!

What’s shrinkage?

The short answer? Your metal piece is going to be a little smaller than your wax piece, because metal shrinks when it cools. How much smaller depends on the caster and what their shrinkage rate is (most common rate I’ve heard is 5-7%).

Want a long answer? Ask your caster. They’ll be able to give you all the details on their shrinkage rate. That way the answer is customized for you.

Lost wax vs mould

There is a difference in the amount of shrinkage when you lost wax cast a piece and when you mould it. There is more shrinkage in moulding a piece. And from my experience, there isn’t that much shrinkage in lost wax casting.

This post is only about shrinkage in lost wax casting. I’ll cover shrinkage with a mould in a later post.

So FINALLY, here is how I make my waxes.

Rings

I like to make rings to fit

My reasoning: Cleaning off the casting surface and polishing will make the ring size bigger again if there is a small amount of shrinkage.

Also, I always put rings on a mandrel and gently tap them round with a mallet. Sometimes rings get bend out of shape a bit in the whole casting process. What at first looks like shrinkage might just be a not perfectly round ring. When the ring is tapped round, you’ll be able to see its size.

If there is more shrinkage than I anticipated, I’ll place the ring on a ring mandrel and give it a few hard taps with a mallet. This easily increases the ring size.

This works best for regular/thin rings. The wider and thicker the ring, the more difficult it becomes to hammer the ring size up if there is more shrinkage than anticipated (also, be careful hammering rings with hollow parts, you don’t want to hammer a dent in it!). For bigger rings, I usually make the size just a tiny bit bigger.

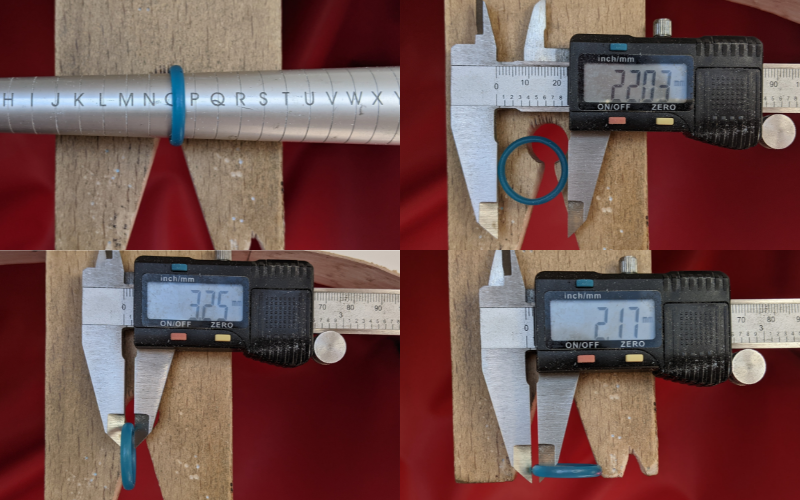

Ring shrinkage demonstration

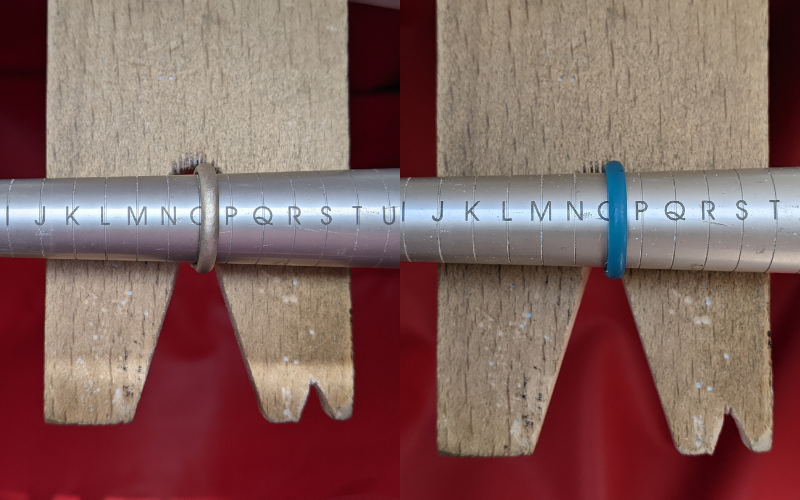

Here is the ring I send to casting

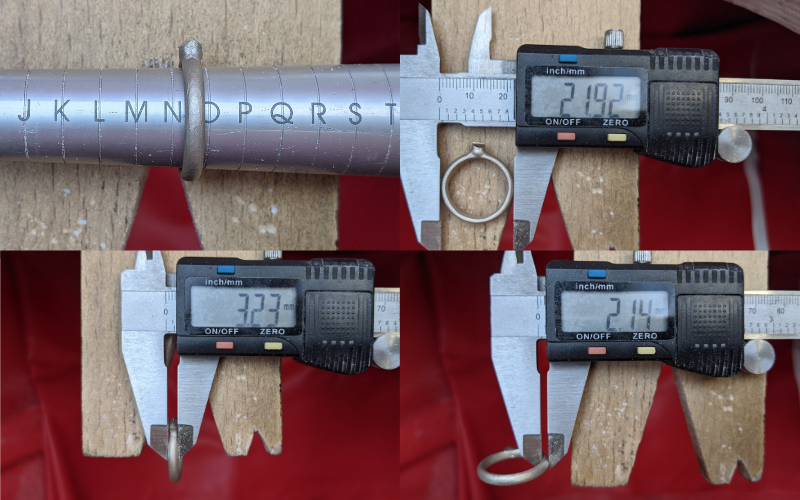

And this is the silver ring I got back. I haven't done any clean up to it yet.

Barely any shrinkage in the width and the depth of the ring. And about half a size smaller.

After tapping it round and spinning out the inside of the ring.

The ring is now the same size as it was in wax!

Settings

I cut the seat of my settings to fit the stone exactly and leave a 1mm setting wall around.

My reasoning: by leaving a 1mm setting wall, I can easily burr the seat a bit bigger in metal if there is shrinkage. The setting wall becomes thinner this way and after cleaning off the casting surface from the outside the setting wall is more manageable.

If the setting wall is still too thick after that, I can file a bevel on the outside to make it easier to push the metal over the stone.

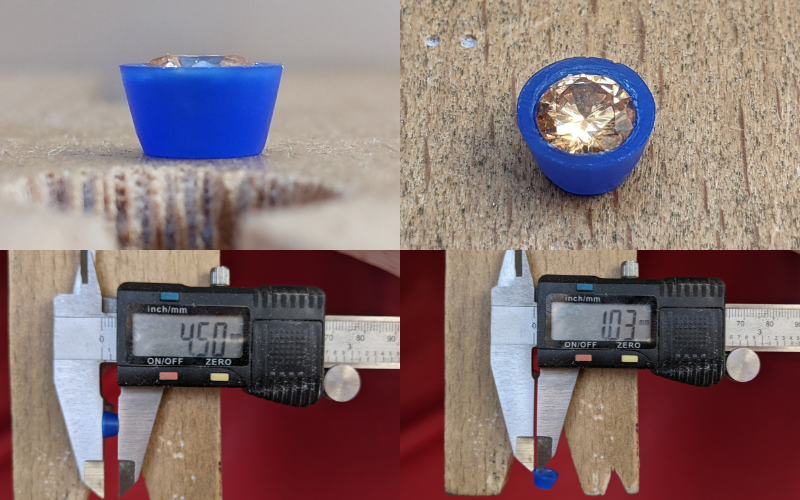

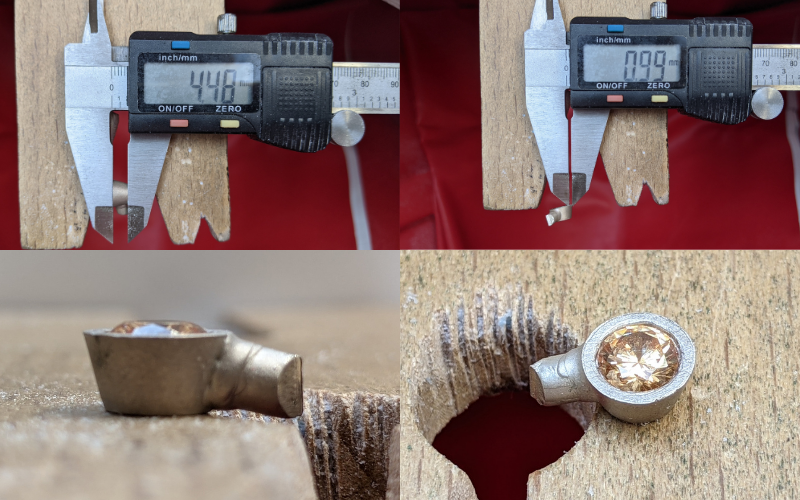

Setting shrinkage demonstration

Here is the setting I send to casting

And this is the silver setting I got back. I haven't done any clean up to it yet.

Barely any shrinkage! The stone still fits, so I don't have to do any work to it to make the stone fit again.

3D shapes

Honestly, I don’t do anything against shrinkage for 3d shapes. I just accept how the piece comes back. For rings, it’s important that the ring size is correct after casting. And for settings, it’s important that the stone fits and there is enough of a setting wall after casting.

But it doesn’t matter to me if my animal carving is slightly smaller in metal than it was in wax.

Every caster is different

I have used different casters in different countries. The quality of the castings and the amount of shrinkage has been different for all of them. What works with one caster, might not work with another.

If you’re still concerned about shrinkage, maybe send in a test piece? That way you can see the shrinkage and find your own way to work around it.

Leave a comment and let me know how you work around shrinkage for your lost wax pieces.