Various casting questions

Huge thank you to Alexandra of Jewels by ADFK who has a casting company in Germany for answering these questions!

Alexandra answered more casting questions in most asked casting questions and why does this happen in casting? in case you want to know more!

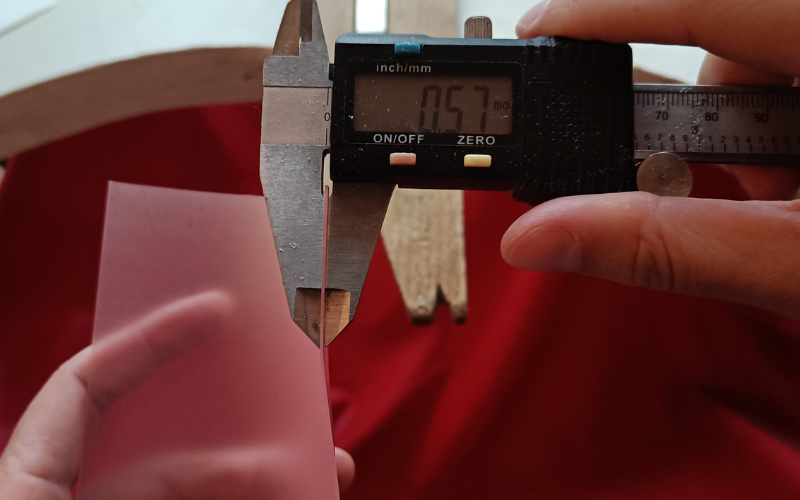

What’s the thinnest measurement you can cast?

If you want to be 100% sure that what you’re making is going to cast, 1mm is the thinnest you can go. It’s a reliable measurement that casts well, and a nice round number that’s easy to remember! Especially if you make bigger pieces, they need to be at least 1mm. Big pieces just need more thickness for the metal to be able to flow through the piece before it cools.

But if you’re up for experimentation, you can actually go thinner! Just look at some of the waxes that are vailable to purchase. Wax wire comes in .8mm, sheet wax comes in .5mm, and the wall thickness of some cowdery profiles is also .5mm. You wouldn’t be able to buy these waxes if they won’t cast!

You just have to create smaller pieces with these thinner waxes, or use them to create details on your piece. It’s also good to remember that the shape of your piece affects how easy it is to cast (you can reread why some shapes are easier to cast here). When you’re already going thin, it might be a good idea to make it an aerodynamic easy to cast shape!

The metal that you choose to cast in affects the outcome as well. Casting thinner pieces is easier in gold than in silver. Gold cools down gradually so it can flow into small spaces longer than silver can.

Just keep in mind that when you go below 1mm the chances of the cast failing become bigger. It’s up to you to decide if it’s worth the risk. I personally love to test the limits of casting by casting test pieces once in a while!

Do moulds need to be recreated?

Yes, moulds suffer from wear and tear. And they do have to be recreated eventually. You should be very happy if you have a mould that needs to be recreated, it means you’re making and selling a lot!

It’s hard to say how long you can use a mould. The material it’s made from, the way it’s stored, and how many times it’s used affect the lifespan of a mould. But in general you can use a mould for a good 10 years before recreating it becomes an issue. It’s always a good idea to keep your master pattern, just in case you’re lucky enough to have a mould remade.

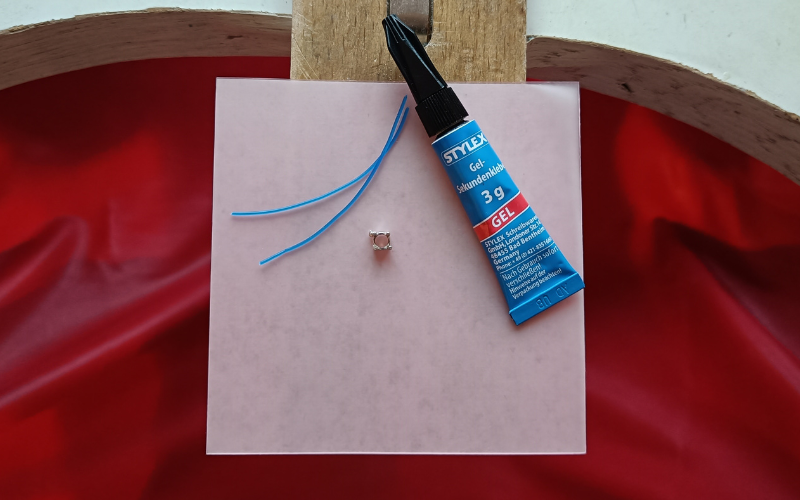

Can you cast with superglue?

I didn’t want to include this question because I’m personally against using super glue. You can use your wax heating pen to repair your wax piece if it needs it!!! But I do get asked this question, so here it is.

Technically yes you can use superglue.

BUT superglue doesn’t burn out as nicely as wax. It can become ashy and get stuck to the walls of the investment. Then when the metal is poured, the ashes mix in and show up as surface imperfections.

Superglue also causes toxic fumes when you burn it so you should DEFINITELY inform your caster if you decide to use it. They might want to adjust the burn out time and use extra ventilation.

So yes you can use superglue, but really you shouldn’t. Practice using your wax heating pen! The more you practice, the better and more confident you become. And before you know it you can repair any broken pieces before you send them of to casting.

More questions?

If you have a different question about casting let me know! I'd love to write more blog posts about this topic!